Enzymes are widely accepted to improve the utilization of nutrients in poultry diets and increase the capacity of birds to perform on less digestible feed ingredients. However, increasing volatility in raw material prices for feed ingredients and stricter regulations on feed safety to control salmonella in poultry production, are changing the way we formulate and process poultry diets and requires more sophisticated enzyme technologies to maximize the efficacy of enzyme solutions

Matching dietary substrate levels

Both wheat and corn are highly variable in the amount of energy, which the bird is able to metabolise and the majority of phosphorus is present as phytate, a substance which is unavailable to the bird. The most common feed enzyme used in poultry diets is phytase, which releases phosphorus bound to phytate in grains. This can help to reduce the dependence on supplementary inorganic phosphorus. Furthermore E.coli phytases have also been shown to be highly effective against the antinutrient effect of phytate and thus also help to increase the availability of dietary energy and protein in the bird. There is increasing independent evidence to show that both carbohydrase and protease enzymes can offer an advantage on top of phytase in poultry diets. This is because these enzymes are able to release extra energy from the starch in corn. Around 65-70% of the energy in corn is derived from starch, however not all of it comes in an easily digestible form and digestibility has been shown to be highly variable between batches of corn. For wheat, on the other hand, energy digestibility generally depends on viscosity, which is caused by the presence of soluble fibres in the grain – this too varies from year to year

Specific enzymes can be used to target the substrates which are reducing the availability of energy in diets and thereby significantly increase the digestibility of dietary energy. For corn-based diets the most relevant enzyme activities have been shown to be xylanase, amylase and protease Xylanase breaks down cell walls to expose starch for digestion. Protease helps to release the starch encapsulated by, and bound to, storage proteins. Amylase, a starch-digesting enzyme, can be added to the diet to help the bird digest starch. Xylanase also reduces the viscosity of wheat, which in turn reduces variability in the availability of energy to the bird in wheat based diets. Wheat viscosity is linked to the presence of non-starch polysaccharides (NSPs) such as arabinoxylans, which xylanase degrades

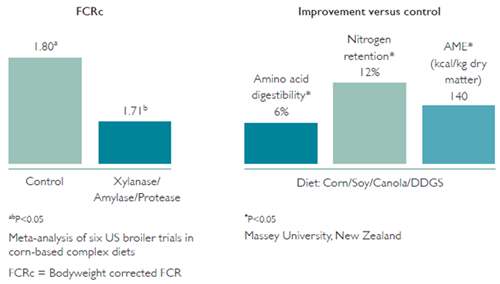

As higher levels of cheaper alternative raw materials, such as corn DDGS, barley, wheat and rape seed meal are used in poultry diets the levels of potentially problematic substrates will increase. For example, the level of arabinoxylans in a corn-soy based poultry diet will increase by approximately 25% in response to including 10% DDGS into the diet. Therefore the nutritionist needs to be aware of these substrates and how much their levels are changing in response to raw material usage in order to determine appropriate enzyme additions. Danisco Animal Nutrition is a pioneer in feed enzyme technology and analyzes over 1000 grain samples a year to assess changes and variability in substrate levels for enzymes in poultry diets. Optimizing the combination of xylanase, amylase and protease to match the relevant substrate levels in modern, more complex poultry diets including corn DDGS has led to increased flexibility in formulating cheaper diets without negative impact on performance of birds in the US (Figure 1). More recently a xylanase and beta-glucanase combination developed by Danisco Animal Nutrition was approved for the use in EU poultry diets to match the substrate levels of mixed grain diets including wheat and barley and increase the consistency of performance in birds fed these diets

Figure 1. Performance and digestibility benefits from the addition of a combination of xylanase, amylase and protease enzymes (Axtra XAP) to complex diets based on corn and containing DDGS. Phytase at 500 FTU/kg feed in all diets

Enabling more effective salmonella control

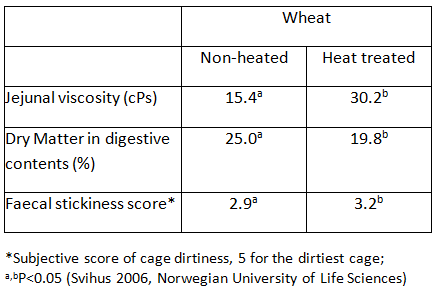

Concerns over food safety and feed hygiene have resulted in feed mills often using pelleting temperatures of 90- 95°C. Processing poultry feed ingredients at high temperatures not only risks destroying heat sensitive nutrients and feed additives but also leads to increased starch gelatinisation and fibre solubilisation. This causes an increase in viscosity of the digesta, leading to poorer nutrient absorption and sticky droppings (Table 1). Furthermore trials showed significant decreases in body weight gain by up to 7% and a poorer feed conversion ratio (4.4%) in broilers

The viscosity in wheat is linked to the significant amounts of non-starch polysaccharides (NSPs) such as arabinoxylans present in wheat. Soluble arabinoxylans increase the viscosity of the digesta in the small intestine, which reduces the digestion and absorption of nutrients and thereby reduces the availability of energy to the bird. Xylanase is an enzyme which will degrade arabinoxylans and therefore offers the means of reducing viscosity in wheat based diets and hence reduce the variability in the utilisation of energy by the bird. The incidence of sticky droppings will also be reduced by xylanase addition. The issue of feed enzyme stability during conditioning and pelleting therefore becomes highly relevant, when trying to meet feed hygiene requirements

Table 1. Properties of gut contents in broilers fed pelleted diets based on 77% wheat, either non-heat-treated or pelleted at 90ºC.

Advanced enzyme solutions can stand the heat

As the pelleting temperatures of poultry diets increase more sophisticated technologies are required to protect enzymes from the heat, to ensure their bioefficacy in the animal. Thermo Protection Technology (TPT), a patented coating technology developed by Danisco Animal Nutrition, has been found to be highly effective in protecting their second generation E.Coli phytase from heat. This coating technology enabled a recovery rate of 96% after exposure to feed pelleting temperatures of up to 95ºC, under very precisely controlled processing conditions. Trials have also proven a fast release of phytase activity from Phyzyme XP TPT in the gut, with a bioefficacy equivalent to the uncoated product in mash diets. Danisco Xylanase, is an inherently more heat stable xylanase and does not require coating to remain stable at pelleting temperatures of up to 90ºC.

Conclusion

In order to meet the demands of increasingly more complex poultry diets and safer feed, effective enzyme solutions require the right combination of activities to specifically match the relevant substrates in the diet and achieve high tolerance to heat. The use of enzyme solutions should ideally be combined with software tools to determine the optimum dosage to maximize cost effectiveness in the diet

ساحة النقاش